The engineer at the New Zealand company wiivv Chris Bellamy had big plans for the 2018 Boston Marathon: he wanted to cover the 42.2-kilometer run with his 3D-printed flips-flops. Choosing shoes is an important preparation for a marathon runner and Bellamy has therefore set itself the goal of proving the quality of its self-developed and individually adapted flip-flops from the 3D printer. And he succeeded: The wiivv engineer was able to finish the marathon in less than 3 hours, even under very difficult weather conditions.

After the Olympic Games, the Boston Marathon has the longest tradition of any marathon race in the world. Every year since 1897, numerous athletes have started on Patriot’s Day to cover the distance from Hopkinton to Boston in the American state of Massachusetts.

Contents

Bet gets Bellamy to run the marathon in 3D printed flip flops

However, before a runner is ready for the marathon, long and intensive marathon training, a healthy and balanced diet and the selection of the optimal running shoes are required to optimally support the foot and absorb the load as well as possible. Chris Bellamy probably differs the most from his competitors when it comes to choosing the shoe for the famous marathon, because he opted for his self-developed flip-flop from the 3D printer.

From the individual scan to the personally fitted shoe ©wiivv

Whereby decided is perhaps not entirely correct in the face of the facts, because the decisive reason for his choice of shoes was a bet.

The point was that Bellamy promised to run the marathon in his 3D-printed flip-flops if more than 500,000 US dollars were raised for the company Wiivv as part of a crowdfunding campaign.

“If everyone said our flip-flops are impossible, I bet I can run a marathon in them (…). We’ve redesigned every part of the traditional flip-flop to create the most comfortable, streamlined sandal ever created. I kept that marathon in mind every step of the way,” said Bellamy.

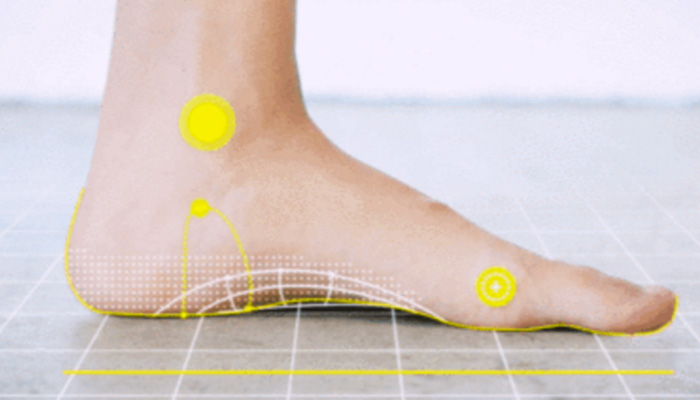

The scanner captures 200 points of the foot as a template for the 3D print ©wiivv

3D printed custom flip flops as a better athletic shoe

The 3D-printed flip-flop is precisely adapted to Chris Bellamy’s foot. This is possible because 200 points of the foot are measured with the help of an app, which creates a perfect model that can be realized 1:1 with the help of the 3D printing process. Bellamy’s footwear is not only personalized, but individually tailored to him or his feet in its entirety.

Every single pair of Wiivv shoes is completely different from each other and can be regarded as a one-off. The pre-orders in the USA are already under way via the official website of wiivv and sales should start in the summer.

© wiivv

Despite the bad weather: Bellamy finishes the marathon in under 3 hours

But back to our marathon runner in 3D printed flip flops, Chris Bellamy. How did the engineer do in the Boston Marathon?

The time on the clock was exactly 2:59:36 when Bellamy crossed the finish line in his flip-flops. In the difficult weather conditions of this year’s run, Bellamy was able to gain another benefit from the flip-flops: While other runners stopped to adjust their shoes for the rainy weather, Chris Bellamy saved this time.

The end time of his is also very decent all in all, especially considering that while his 3D printed shoe is designed to fit his foot perfectly, it lacks any support for the foot due to the open design of a flip flop ankle is missing.

Now that you know it, would you run a marathon in wiivv’s 3D printed sandals?

Tell us what you think and contact us. Would you like a summary of the most important news in 3D printing and additive manufacturing directly and conveniently in your mailbox? Register now for our weekly newsletter and follow us on Facebook, Twitter and Google+ to stay up to date! You can also find us on XING and LinkedIN.