Contents

How do I create a NPT thread in Solidworks?

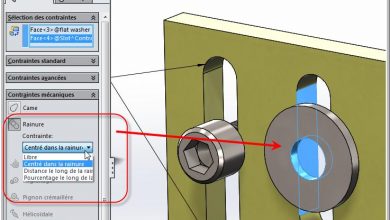

Utilizing the Hole Wizard Feature Set the standard to ANSI Inch, set Type to Tapered Tap Pipe Tap and in the hole specifications, select the desired size in inches. The next step is the End Condition which defines the total length of the thread, it can be left as the default value or customized to a specific distance.

How do I thread a hole in Solidworks?

Make sure the “With Thread Callout” option is checked otherwise the tap program in SOLIDWORKS CAM will not function. Once the hole specifications are selected, choose the “Positions” tab at the top of the Hole Wizard property manager. Choose a face to place the tapped hole on. Click to place a hole or multiple holes.

What thread is NPT?

The best known and most widely used connection where the pipe thread provides both the mechanical joint and the hydraulic seal is the American National Pipe Tapered Thread, or NPT. NPT has a tapered male and female thread which seals with Teflon tape or jointing compound.

How is NPT thread calculated?

The taper rate for all NPT threads is 1⁄16 (3⁄4 inch per foot) measured by the change of diameter (of the pipe thread) over distance. The angle between the taper and the center axis of the pipe is 1° 47’′ 24″″ (1.7899°).

What size is 3/4 NPT?

For example, a 3/4″ NPT pipe thread has an outside diameter of 1.050 inches. Each thread size has a defined number of threads per inch (TPI).

How do you add cosmetic threads in SOLIDWORKS 2020?

To insert cosmetic threads from assembly documents into drawings, click Insert > Model Items and click Cosmetic thread . In drawings, Insert Callout appears in the shortcut menu.

How does the thread lift work?

A thread lift is a type of procedure wherein temporary sutures are used to produce a subtle but visible “lift” in the skin. … As the skin grows weaker, it’s no longer able to support the tissues beneath it adequately, meaning that gravity pulls it downwards and stretches it.

What is the difference between tapped hole and bottoming tapped hole?

the only difference what i could find is that the drill depth. Tapped hole have aproximately 2mm more drill depth when compared with bottoming tapped holes.

What is a counterbored hole?

A counterbore (symbol: ⌴) is a cylindrical flat-bottomed hole that enlarges another coaxial hole, or the tool used to create that feature. A counterbore hole is typically used when a fastener, such as a socket head cap screw, is required to sit flush with or below the level of a workpiece’s surface.

How do you add thread to a hole?

Keep the tap perpendicular to the metal and keep the handles of the wrench parallel to the metal. Slowly turn the wrench clockwise, pushing down with firm pressure. The tap will begin to cut threads into the inside of the hole. Continue pushing and turning until the tap goes clear through, past the bottom of the hole.

Do NPT threads need Teflon tape?

NPT threads are designed to be used with a sealing compound such as Teflon tape to create a leak-free seal, whereas NPTF threads form a mechanical seal by crushing the entire thread form. If NPT is used without a sealing compound then there can be leakages or other unpleasant issues.

Does NPT fit BSP?

NPT and BSP threads are generally not compatible due to the differences in their thread forms. NPT threads have a 60° included angle and have flattened peaks and valleys (this is a Sellers thread form); BSP threads have a 55° included angle and have rounded peaks and valleys (this is a Whitworth thread form).

How far do NPT threads engaged?

As a general guideline, after hand-tight engagement, tighten 2 full turns for sizes up to 1 inch for NPT thread fittings. You should have between 3.5 and 6 engaged threads. Any number outside of this range may indicate either under or over tightening of the joint or out of tolerance threads.

How deep should a NPT tap go?

Most standard pipe taps have a maximum chamfer length that ranges between 3 and 4 threads. Therefore, the tapping depth should be the approx. 5 threads for the “hand tight”, 3 threads for “wrench tight”, and 4 threads for the chamfer, or approx. 12 threads total.

What is difference between NPT and BSP thread?

Both NPT and BSP are pipe thread standards for screw threads used on pipes and pipe fittings to seal pipes. … With NPT, the peaks and valleys of the threads are flat. In BSP, they are rounded. Secondly, the NPT angle of the thread is 60 degrees and the BSP angle is 55 degrees.