Contents

Dentures in particular are increasingly being manufactured using 3D printing

Medicine, including dentistry, is undoubtedly one of the many areas in which digitization and, in particular, 3D printing technologies will bring drastic changes in the near future.

In this sense, 3D specialist Hans Langer already expressed himself in March 2014: “In the dental environment, additive manufacturing has already become a real series application. The dentures manufactured with our technology have almost completely replaced the previous investment casting in some countries. Currently,” Langer said at the time, “about 6.8 million units are manufactured using this process every year, and the trend is rising.”

In principle, however, a distinction must be made between 2 different (admittedly related) forms of computer-aided production, both of which belong to the service portfolio of 3D Activation:

1.) Using 3D scanning technology to create digital tooth models.

2.) The actual production of dentures using a 3D printer.

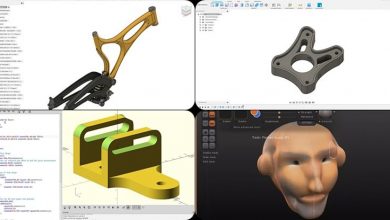

3D scanning using CAD/CAM technology

In the first area, CAD/CAM technology (= Computer Aided Design or Computer Aided Manufacturing) is a well-established solution that was developed in 1985-87 by a team led by Professor Werner Mörmann (University of Zurich). A camera (or now mostly a small-sized scanner) takes pictures of the patient’s diseased tooth. The digital images obtained in this way are then converted into a 3D model. Based on this model, the inlay or crown can be produced – traditionally by milling using a form grinding machine or, as is often the case, on a 3D printer.

The dentures directly from the 3D printer

For a long time, the direct 3D printing of dentures from CAD/CAM-generated data faced the hurdle that no printable materials suitable for the intended purpose were available. However, this problem has now been solved, thanks to the spread of ceramic printing that has now taken place. Ceramic not only offers the desired material properties, it also scores with the biocompatibility that is indispensable for use in the mouth. Not to be forgotten is the perfect, namely “tooth-colored” appearance, in which ceramics can be processed.

More benefits for the patient

Thanks to CAD/CAM technology, the patient no longer has to put the inconvenient impression tray and impression material in their mouth. The subsequent ceramic print saves the patient from having to chew on a “temporary” for several days, since the denture can be printed out on the same day.

To services