Contents

Everything to consider when designing wall thicknesses for 3D models

One of the most sensitive details when distorting 3D files is without a doubt observing the typographical and mechanical requirements for stable wall thicknesses. At the same time, it is sometimes difficult for those interested in 3D printing to understand why not everything that may be desired in terms of wall thicknesses can unfortunately be implemented in 3D printing.

We would therefore like to answer a few basic questions about planning wall thicknesses when creating 3D models.

The harder the material, the thinner the walls can be

Of course, it should be noted at the outset that the minimum possible wall thicknesses vary considerably depending on the material. Specifically, these range from 0.3 mm for metal (in selective laser melting) to 2 mm each for polymer plaster (in ColorJet printing) and PMMA or quartz sand (each processed in FDB printing). A clear connection can be seen from this: the harder the starting material selected for the 3D model, the thinner the possible wall thicknesses.

In the case of metal 3D printing, the possibility of printing very thin outer walls is one of the great advantages of this innovative technology compared to conventional metal processing techniques. Very filigree forms can be implemented in this way, which would not be possible with such attention to detail with milling or welding.

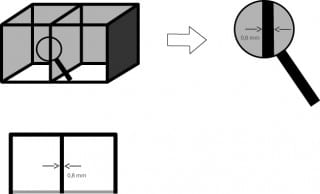

The following graphics should make the construction of wall thicknesses and their lower limits as clear as possible. The values entered in the models refer to the SLS pressure PA plasticas this material is by far the most frequently requested by our customers.

Construction of the outer walls of a PA model

Construction of partition walls in SLS pressure models made of PA

At least 1 mm wall thickness is required in SLS printing for loose walls within the model

These models should serve as a guide and at the same time make it clear to you which forces act on the interior and exterior walls during the printing process as well as during transport and use. Of course, we are happy to advise you on the construction of your 3D model or do it for you.

You can find out more about wall thicknesses in 3D printing on our website, where you can also find lots of other information about materials, printing processes and services.

Go to My 3D Files