Pellenc, manufacturer of equipment for green spaces, from the harvester to tree pruning tools, has invested heavily in R&D to promote its growth. Pellenc used 60 licenses of SOLIDWORKS CAD 3D and SOLIDWORKS Flow Simulation for product development, but much of the aesthetic and ergonomic design was outsourced.

In order to eliminate the challenges encountered when integrating the hard-copy model or 3D surfaces provided by designers into SOLIDWORKS CAD, Pellenc turned to SOLIDWORKS Industrial Designer. Managing industrial design work in-house also had to make it easier for the company to innovate and respond to market needs.

After only a few days of using SOLIDWORKS Industrial Designer, Pellenc designers were able to easily model complex shapes and iterate different concepts, even after transferring the models to SOLIDWORKS.

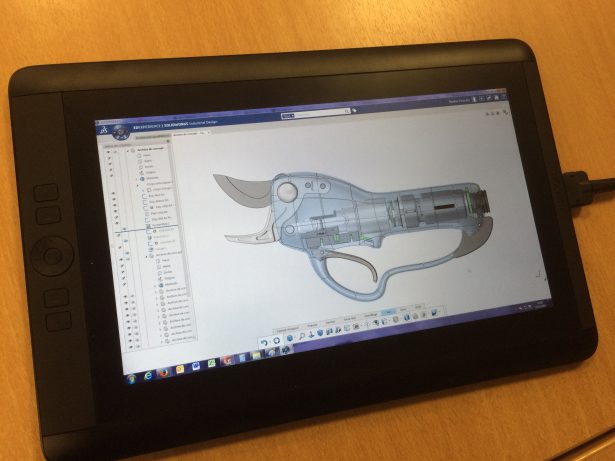

One of the first projects designed in Industrial Designer was a new line of pruning shears, developed to achieve the best power-to-weight ratio on the market. The secateurs had to offer a high handling capacity, a very compact size and a small battery that would run all day. The design also had to be attractive and ergonomic to the point that the pruning shears would appear to be an extension of the hand.

Pellenc developed the secateurs by creating the mechanism on SOLIDWORKS CAD and designing the shell around it using a freehand sketch on a tablet. A free-form volume very similar to the sketches was then created. Pellenc engineers combined the free form with parametric functions to remove the front of the tool and insert the blade. With SOLIDWORKS Industrial Designer, the company was also able to analyze the clearance space before moving the pruners back into SOLIDWORKS CAD for the next stage of product development.

Pellenc has also benefited from online access to the model, anytime and anywhere. The company was able, for example, to validate a mold while it was traveling to a subcontractor or to modify the part remotely. The collaboration features also allowed the team to share information with all stakeholders, wherever they are, to discuss project progress and make decisions faster.