Contents

How do you make a keyway in Autocad?

Use the Keyway dialog box to enter parameters for keyway feature in the Shaft Component Generator. Ribbon: Design tab Power Transmission panel Shaft. On the Design tab, select Cylinder in the tree control. In the Section features drop-down menu, select Add Keyway groove .

What is a keyway and how is it formed?

noun. a longitudinal slot cut into a component to accept a key that engages with a similar slot on a mating component to prevent relative motion of the two components.

How do you dimension a keyway?

In the English system, it is standard practice to dimension keyways. The hub keyway is dimensioned by its width and depth on the shaft – keyway sides. Referencing Figure 1, the keyway dimension is W x T1. Unless otherwise specified, the shaft keyway is assumed to be standard.

How does a keyway work?

A key and the keyways make up a Keyed joint to secure the hub and the shaft to prevent relative movement between a power transmitting shaft and an attached component. … Keyseat is a recess in the shaft and the Keyway is the recess in the hub to receive the key and thus securely lock the component.

What does C keyway mean?

C keyway is Schlage’s most common key SC1 or SC4 depending on if it’s 5 or 6 pin. A key cut on a generic key blank compatible with a 5-pin C keyway (EZ# SC1 or Axxess+# 68), a common residential keyway. … The keyway is the shape of the keyhole of the lock cylinder into which the user inserts the key.

How much torque can a keyway handle?

where l, the effective length of the keyway, = 25 mm; and h, the keyway depth, = 3 mm. For the keyed shaft, Thus, 228 Nm is the maximum torque that can be transmitted before the 16-mm-diameter keyed shaft plastically deforms.

What’s a keyway?

keyway in Mechanical Engineering A keyway is a slot or groove in which a key slides. A keyway is a long slot cut into a component to accept a key that engages with a similar slot on a mating component so that the two components do not move against each other.

What does key dimension mean?

A dimension key is the primary key of a dimension table. In the example below, the “Time_key” column is the dimension/primary key of the Time dimension. This column will be used to join the dimension with fact tables, just like any other key.

What is feather key?

in machinery. : a sunk key without taper that is permanently fixed in one of the connected pieces and that is a sliding fit in a keyway in the other so as to permit relative longitudinal motion. — called also spline.

How do you show a keyway in drawing?

17.17 shows the method of dimensioning a keyway for a square or rectangular parallel key in a tapered shaft, where the keyway depth is shown from the outside edge of the shaft and is measured vertically into the bottom of the slot.

What is Js9 tolerance?

The advantage of the Js9 tolerance is that the key can be inserted and the gear manipulated without much difficulty. Whereas the P9 tolerance is a press fit tolerance. Once the key is inserted into the keyway, it is not going to move.

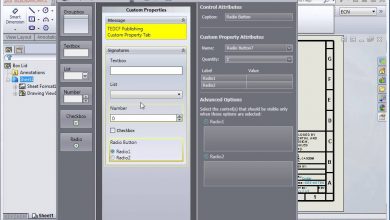

Where is the shaft generator in Autocad?

Description. The Shaft Generator tool is for developing shafts either as standalone parts or within the context of other geometry in an assembly. It is located on the ribbon, Content tab, Shaft panel. Click the large Shaft Generator icon, then select the starting point or click on an existing centerline.

What is the function of the shaft?

A shaft is a rotating machine element, usually circular in cross section, which is used to transmit power from one part to another, or from a machine which produces power to a machine which absorbs power.

What is a spline in engineering graphics?

In its simplest terms a spline is a smooth curve with a constantly changing radius which passes through a set of control points.

What are shop drawings construction?

A shop drawing is a drawing or set of drawings produced by the contractor, supplier, manufacturer, subcontractor, consultants, or fabricator. Shop drawings are typically required for prefabricated components. … The shop drawing normally shows more detail than the construction documents.