If your design doesn’t work in the real world, you may consider it a failure. This is a basic principle that any good designer easily understands. This is also the main reason why physical prototyping has traditionally played an important role for manufacturers in the product development process.

Prototyping allows them to test the physical strength of a new design, assess its actual performance, and ensure that major design flaws are identified and mitigated before the final product is shipped. The result is more reliable products, but the physical process of “design / build / test” has unfortunately so far been associated with additional cost and time in the product development cycle.

Let’s see how things are going in 2018: New simulation tools free designers from their dependence on expensive physical prototypes. Simulation reduces development cycle time and enables manufacturers to bring better products to market, faster than ever before. But above all, the best news is: simulation is no longer exclusively reserved for large manufacturers who have significant financial resources.

Powerful simulation tools

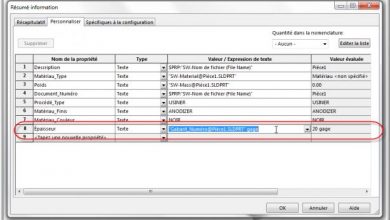

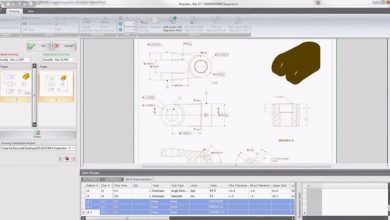

Simulation is a simple, easy, and cost-effective way to create products that exceed customer expectations. If you are using SOLIDWORKS®, you are already familiar with simulation features.

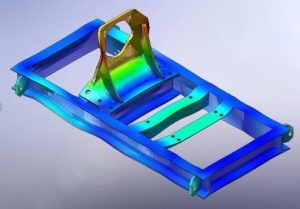

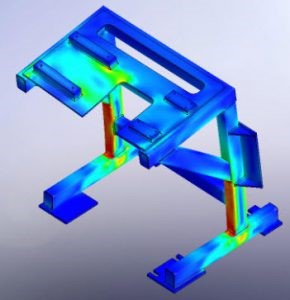

SOLIDWORKS Premium includes motion analysis and structural analysis tools that allow designers to simulate the effects of real forces and movements on their products. They are thus able to accurately assess the soundness of a design and identify potential weak points or excessive design of components. These tools make it possible, for example, to more easily make assumptions about the behavior of the materials used for the components. This makes it possible to find solutions more quickly. In addition, it is possible to perform simulations during the design process rather than at its end.

Simulation is a game-changer for designers, but the simulation and analysis capabilities built into SOLIDWORKS Premium only scratch the surface and open up a whole new world of testing opportunities when transitioning to SOLIDWORKS Simulation Standard and Professional.

SolidWorks Simulation Standard

When it comes to identifying and testing the weak spots in a design, the right tools can make all the difference. SOLIDWORKS Simulation Standard software provides a better understanding of the strengths and weaknesses of a design with minimal effort.

The best tools allow you to make better decisions

The following features are included with Simulation Standard. They allow you to easily validate the performance of your design.

Trend

Using simulation as part of the design process makes sense, as the results can highlight issues that would otherwise be undetectable. However, as a design evolves, it can be difficult to identify the effects of the changes. The Trend Chart allows you to define a benchmark data analysis and easily compare the impact of design changes based on key criteria, such as maximum stress or maximum displacement.

Fatigue simulation

Most structural failures in metal components are caused by fatigue. Even when a component is subjected to stresses below the yield strength of the materials it is made of, failure can occur if it undergoes a repetitive load cycle. SOLIDWORKS Fatigue Simulation provides a better understanding of how repeated or random load cycles can cause structural breaks in your design due to the level of fatigue imposed on components. Component fatigue analysis shifts from parts “designed to withstand” to parts “designed to withstand life”.

Time-based motion simulation

Temporal motion analysis is a method of evaluating the physical motions of an assembly where components move over a period of time. This approach adds an authentic “physical reality” to the movements of assemblies. It takes into account gravity, friction and mass. This makes it possible to calculate the movements and bonding forces that apply to the assembly body under external (environment) and internal (motors, springs, etc.) loads.