Anyone at AU this week will surely take note as AutoCAD customer Skystone enters the limelight. Autodesk News unveiled that the New York-based contractor will soon erect the world’s tallest volumetric modular hotel at 26 stories—an AC Marriott in the heart of Manhattan.

Skystone is reinventing how buildings are constructed by offering cost efficiency and high quality to developers in a compressed timeline with the added benefits of less waste, noise, and congestion-causing shipments and staging of materials versus traditionally constructed projects.

Contents

In the Making

Skystone is manufacturing fully completed modular hotel rooms—including all finishes, furniture, and equipment—in a manufacturing facility in Poland and shipping them to New York City on a single vessel.

When the modules arrive in New York Harbor, they’ll traverse the Brooklyn Bridge and get stacked one by one on the 6th Ave. construction site, ultimately creating the world’s tallest modular hotel.

Autodesk is providing end-to-end project delivery software that allows Skystone to innovate big on how hotels are constructed. AutoCAD and Revit are used for design, with BIM 360 and Assemble used throughout the end-to-end project delivery process.

AutoCAD’s Role

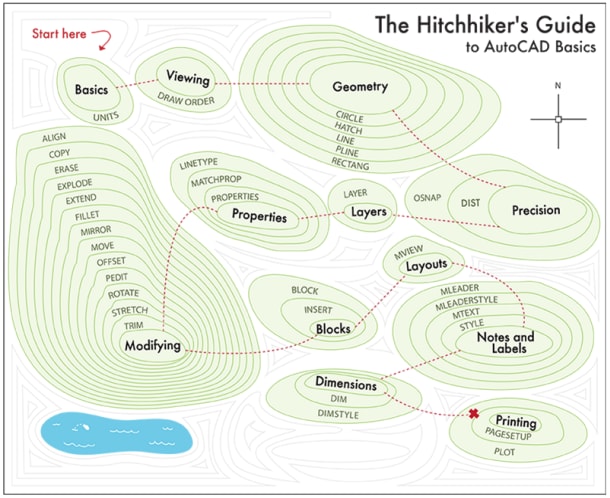

AutoCAD is an essential part of Skystone’s design process and provides much needed insight as the company works with many different parties for this project, from subcontractors to engineers to peer reviewers. DWG is a common currency of this entire process.

AutoCAD files first come in from consultants, and make it all the way to the fabrication drawings on the shop floor. On the front end of the design phase, Skystone brings subcontractors’ DWGs into Revit as 2D underlays to make sure subcontractors stay connected to the Building Information Model. AutoCAD is a key enabler to input to Navisworks in order to see whether or not things jive on the project and determine whether or not they’re going to fit.

On the back end of the factory side, Skystone takes 2D drawings and exports them from Revit as CAD files, enabling them to fabricate the components for the module. At this point subs can start to layout sheet metal, fabricate components for the module, etc.

“AutoCAD is a critical part of the modular design process of the world’s largest volumetric modular hotel and others we’ve worked on,” said Greg Thompson, CFO, Skystone. “It’s really the glue that holds the project together as it offers a common language for communication, both in the office and onsite via the AutoCAD web and mobile apps.”

Modular Means Convergence, Better and Faster Building

As the global population increases and cities become even more crowded than they are today, we need to improve the way we build things. The convergence of manufacturing and construction is redefining the future of making. In Skystone’s modular approach, buildings are being built better and nearly 25 percent faster. And workers are able to work more efficiently in a controlled environment on the front end, rather than harder on the back end.

The construction process more closely resembles a manufacturing one, with work moving away from the unpredictable environment of a construction site into a more predictable one: a well-run factory. This means fewer delays due to weather, less foot traffic at the job site and less risk of injuries.

We are proud that AutoCAD is an important part of helping Skystone build some of the world around us—one modular room at a time.

Source: Autodesk