Contents

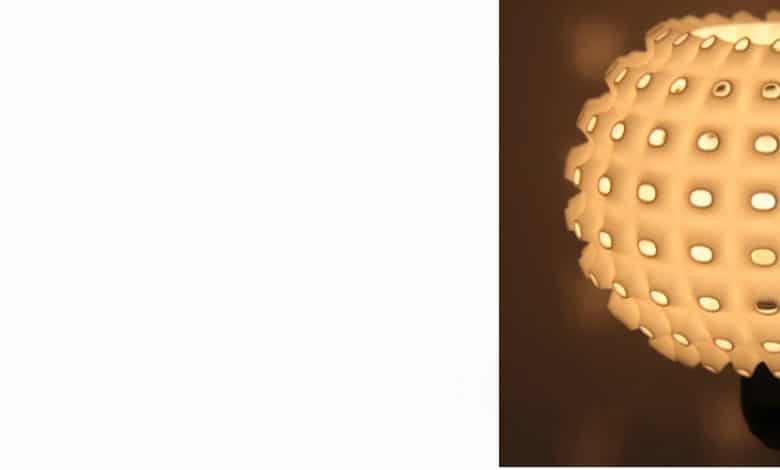

New lighting concepts could be easier to implement thanks to PMMA 3D printing technology

PMMA offers the solution to a fundamental problem of the transition from analog lighting concepts to digital LEDs is the fact that the usually long production cycles industrial production cannot keep up with the speed at which improvements in LED lighting concepts are being achieved. However, the lighting manufacturers’ business model is usually based on the fact that high-volume products must be developed quickly and efficiently in order to be able to sell obsolete components in good time.

3D printing technology offers a solution to this problem, as rapid prototyping eliminates the need for upfront investment in molds and inventory is easily in CAD files can be saved, which can be modified in the event of changes to the design and appearance without loss of investment. So the finance departments of lighting manufacturers no longer have to write off obsolete inventory, and the sales force no longer has to try to get rid of obsolete mass-produced inventory. At the same time, thanks to the components from the 3D printer, individualized designs and small series become economically profitable.

PMMAs as a way out

In the Netherlands, a new 3D printing process based on PMMAs (polymethyl methacrylates) is now being used. The decisive advance of this innovative 3D printing technology lies in the speed of the process. Instead of building in layers with comparatively slow 3D printers (such as in the FDM process, also known as fusion layering), this 3D printing process uses fast inkjet printers used to print lenses and optical surfaces. A special process called “Fluent Dynamics” (= flowing dynamics) ensures particularly smooth surfaces of the 3D print models, thus avoiding a problem of many conventional 3D printers when printing surfaces. The printed surfaces of the PMMA 3D print models thus achieve their maximum optical functionality without polishing or other post-treatment.

Another advantage of the Dutch PMMA 3D printing technology is that this rapid prototyping process enables the creation of so-called free-form optics allows. Freeforms consist of a basic structure for beam deflection or for focusing on the target (= special lens layer) and a fine structure for intensity redistribution and allow almost any light distribution due to this construction.

3D printing enables the right lighting for every location

Thanks to lighting concepts generated by 3D printing, every street lamp could be one in the future individually designed optics that ensures that its light distribution exactly matches the street to be illuminated at the planned location. Appropriate applications are of course also possible indoors.

You will find numerous suggestions for the realization of 3D printing ideas with PMMA and numerous other materials (including quartz sand) and 3D printing processes at 3D Activation. Our 3D printing service from Wiesbaden and Thun/Switzerland has set itself the goal of helping you to implement 3D printing projects, including innovative lighting concepts. For this purpose, simply look at our website or contact our customer service.

To contact form