Contents

ColorJet Printing and Selective Laser Sintering: The most important differences and similarities

While other 3D printing processes are either solid (like FDM and metal 3D printing) or liquid (like stereolithography and polyjet 3D printing), the raw materials used in selective laser sintering (also known as SLS 3D printing) as well as in Color Jet Printing (also referred to as CJP 3D printing) in the form of a powder before. It therefore seems particularly interesting to compare these two powder 3D printing processes with each other, especially since, despite the parallels in the 3D printing material, they are 2 completely different rapid prototyping processes.

Melting versus sticking

The most important difference between SLS and CJP 3D printing is quickly explained: while the powder is being processed in selective laser sintering melted The structure of the 3D print object in Color Jet Printing takes place via gluing. From this difference follows the use of different materials, namely polyamide (PA) in SLS 3D printing, polymer gypsum in CJP 3D printing.

With color jet printing, an ink jet (similar to that of an ink jet printer in the 2D area) is used liquid binder applied to a thin layer with powder (polymer plaster). The print heads of the Color Jet Printing 3D printer are moved over the print bed filled with polymer plaster, on which the 3D print patterns specified in the CAD file are then printed. The powder is applied precisely and evenly to the build platform, which grows layer by layer. Without the need for an additional support geometry (support), the 3D print models are thus consolidated in the powder bed. Excess polymer plaster is automatically sucked off.

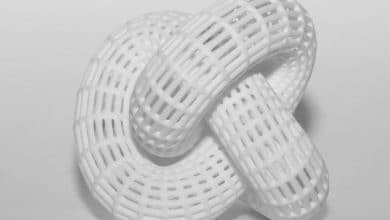

Selective laser sintering works via the local merging individual layers of powder, with the laser beam in the PA powder precisely tracing the contours constructed in the 3D file and thereby selectively fusing the material into a break-resistant 3D printed object.

SLS 3D printing also differs from the CJP process in its much more selective way of working.

Incidentally, selective laser sintering is one of the older 3D printing processes. This rapid prototyping process was invented by Doctor Charles Deckard (from the University of Texas, Austin) in 1986 and has been used in industrial production since 1992. Color Jet Printing entered production in 1994.

The different surface structure of the finished 3D printed models is also particularly important. The typical rough surface Polymer gypsum objects created in CJP printing is noticeably different from the rather smooth surface you find in PA/SLS 3D printed models.

Another important difference is that in Color Jet Printing full color 3D printed objects are possible, while SLS 3D printed objects are basically monochromatic. As a rule, the PA 3D prints turn out white, whereas PA-Black enables completely black objects.

3D selfies as a classic area of application for color jet printing

A typical field of application for polymer gypsum objects from Color Jet Printing with polymer gypsum are 3D selfies, which have enjoyed increasing popularity in recent years. A further field of application are means of presentation and display models, especially in the field of architecture.

Selective laser sintering with PA plastics is primarily used where moving parts are required, for example in tool and prosthesis construction, but also in the art and design sector.

Both polymer gypsum and PA plastic objects can be used finishing Post-treat mainly by infiltration (to protect against contamination and to increase stability) and by painting. If you want metallic properties, electroplating is an option. Of course, you can also have PA models colored after 3D printing, while this should be irrelevant in the case of full-color CJP 3D printed polymer gypsum objects.

3D printed objects made of polymer plaster and PA plastic, as well as various other materials (including ceramics) are available from the 3D Activation 3D printing service. On our website you can find out, among other things, which 3D material is best suited for your model.

Go to My 3D Files